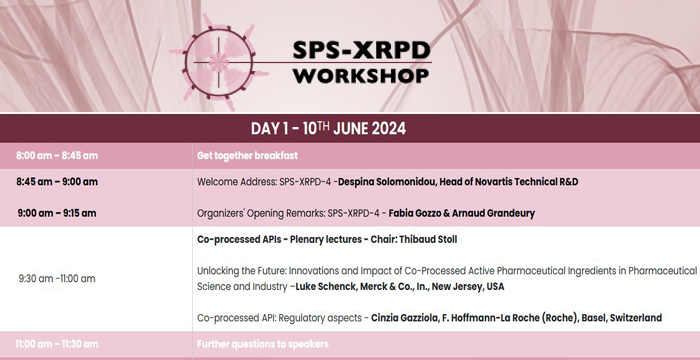

The 4th Spring Pharmaceutical Synchrotron X-Ray Powder Diffraction Workshop was held June 10-11, 2024, at the Novartis campus in Basel, Switzerland. The SPS-XRPD workshops are a collaborative effort between Excelsus Structural Solutions in Switzerland and Purdue University, Argonne National Laboratory, and Improved Pharma in the United States. These workshops bring together experts from the pharmaceutical industry and the Synchrotron X-Ray Powder Diffraction (XRPD) community. They aim to address challenges in pharmaceutical R&D, explore synchrotron-XRPD opportunities, discuss the leading edge of the technology and recent relevant applications, and facilitate open discussions. This year, the workshop included a very interesting session on the exploration of co-processed active pharmaceutical ingredients (APIs). Guest lecturers provided insight into what co-processed APIs entail, how they are regulated within the pharmaceutical industry, and how they are best characterized.

The 4th Spring Pharmaceutical Synchrotron X-Ray Powder Diffraction Workshop was held June 10-11, 2024, at the Novartis campus in Basel, Switzerland. The SPS-XRPD workshops are a collaborative effort between Excelsus Structural Solutions in Switzerland and Purdue University, Argonne National Laboratory, and Improved Pharma in the United States. These workshops bring together experts from the pharmaceutical industry and the Synchrotron X-Ray Powder Diffraction (XRPD) community. They aim to address challenges in pharmaceutical R&D, explore synchrotron-XRPD opportunities, discuss the leading edge of the technology and recent relevant applications, and facilitate open discussions. This year, the workshop included a very interesting session on the exploration of co-processed active pharmaceutical ingredients (APIs). Guest lecturers provided insight into what co-processed APIs entail, how they are regulated within the pharmaceutical industry, and how they are best characterized.

Co-processing refers to methods that improve the properties of drug substances without using classical approaches like changing solid forms, changing formulation, or focusing on polymorphs. Examples of co-processing include systems where a second component, typically an excipient or additive, is processed with the API to form a composition with improved properties. This includes the formation of small particle size material in the range of 1 to 25 µm or surfactant compositions including the API that have enhanced properties. One of the goals is to prepare particles optimized for continuous direct compression (DC) processing.

Dr. Luke Schenck provided an insightful summary of co-processing. He offered several initial definitions and then discussed three cases:

Case One: An API that was unstable when milled or processed due to the formation of an amorphous material. A co-processed polymer composition system was used to avoid steps like drying and milling, resulting in a composition that could be rapidly developed into a material suitable for clinical trials.

Case Two: The need for a crystalline material with a small particle size. Traditional milling methods were unsuccessful. Instead, a processing method was used to achieve the desired outcome, similar to some work done with raloxifene, where it was milled with a surfactant to meet bioavailability goals.

Case Three: Overcoming content uniformity challenges at low drug loading. A mixture composition was prepared in which composite particles overcame content uniformity problems.

Dr. Schenck’s presentation highlighted the potential of co-processing in developing pharmaceutical materials with improved properties, facilitating advancements in clinical trials and drug development.

The regulatory aspects of co-processing were covered by Dr. Cinzia Gazziola from Roche. She presented a comprehensive summary of the rulings made by various regulatory bodies regarding co-processed materials.

Early on, the FDA ruled that a co-processed material cannot be approved as a drug substance unless the additives in the co-processed composition are required for stability or safety reasons. In such cases, it is possible to describe the co-processed API as an API and handle it in the regular sense according to ICH Q7. However, she highlighted that different regulatory bodies have different definitions and strategies for co-processing.

She also pointed out that pharmaceutical companies face challenges because access to certain solvents and processing conditions required for co-processing is not typically available at a drug product manufacturing site and is instead handled under ICH Q7. This creates a discrepancy between the goals of co-processing and the regulatory system. The idea is to define the co-processed composition as the drug substance and manufacture it under ICH Q7, but some regulatory bodies want to define the co-processing step as a drug product step and require it to be made in a drug product facility. Another issue related to co-processed material is shelf life, which generally appears to be worked out on a case-by-case basis. This issue is particularly relevant for biologics, as biologic manufacturing is more flexible and can allow the API to be defined as the active substance plus additives.

Dr. Gazziola then discussed an interesting case from Roche involving Zelboraf, a composition containing the tyrosine kinase inhibitor named vemurafenib, which is manufactured using a process that produces micro-precipitated bulk powder. The process involves dissolving the active ingredient vemurafenib and the additive HPMCAS in dimethylacetamide and adding that solution to water or buffer. This produces a micro-precipitated bulk powder that is soluble and suitable for clinical trials. Without this processing, the active ingredient is so insoluble and difficult to manufacture that it would not be available for a wide range of uses and could not be tested in animals under a wide dosage range.

The FDA did not define the micro-precipitated bulk powder as an API. In contrast, the EMEA defined the micro-precipitated bulk powder as an API. Other regions are divided between the FDA and EMEA rulings. Interestingly, although the FDA did not allow the definition of the micro-precipitated bulk powder as a drug substance (API), it permitted its manufacture under Q7 in a drug substance facility. Discussions among the FDA and other interested parties are ongoing as to how such instances will be handled in the future.

Steve Byrn presented a talk on polymorphism. Part of this talk addressed the use of synchrotron analysis for co-processed materials and how this could fit into a drug development scheme. The overall strategy involves fast development of products, and co-processing is extremely consistent with fast development because it allows a quick transition from drug substances to the drug product.

A fast development strategy begins with a screen of the existing forms of the API, generally aimed at selecting the most stable form. The next step immediately moves to co-process screening involving amorphous formulations. Highly recommended is the utilization of hot stage DSC microscopy, which provides visual information on the compatibility of drugs and polymers and also provides thermal analysis and parameters like Tg, which bears on the stability of the co-processed composition. Synchrotron can be used on co-processed material and to verify the amorphous nature of the co-processed composition if needed. If the co-processed composition contains a crystalline material coated, for example, with an additive, synchrotron analysis can determine whether any crystal form changes have occurred during the processing step.

For further reading on co-processed APIs, please refer to the following series of blogs written by Steve Byrn:

-

Co-Processed Pharmaceutical Solids – A General Introduction

-

Co-Processed Pharmaceutical Solids – An Approach to Screening

-

Analytical Methods for Studying Co-Processed Pharmaceutical Solids

References:

Gibson L., Hartauer K.J., Stowers J.L., Sweetant S.A., Thakkar A.I. (1998). Solid Orally Administrable Raloxifene Hydrochloride Pharmaceutical Formulation. US 5811120.

Shah N., Iyer R.M., Mair H.-J., Choi D., Tian H., Diodone R., Fahnrich K., Pabst-Ravot A., Tang K., & Scheubel E. (2013). Improved human bioavailability of vemurafenib, a practically insoluble drug using an amorphous polymer-stabilized solid dispersion prepared by a solvent-controlled coprecipitation process. Journal of Pharmaceutical Sciences, 102(3), 967-981