Our first blog post on co-processed pharmaceutical solids provided a general introduction. A second blog discussed an approach to screening for co-processed pharmaceutical solids. This third blog focuses on analytical methods for studying co-processed pharmaceutical solids.

Analytical methods for co-processed compositions are particularly important to verify the formation of the composition and provide a convenient method for scaling up the process and characterizing the material in a regulatory sense. A good analytical method can greatly facilitate development and reduce time to market by providing a convenient route to specifications, validated methods, and determining stability.

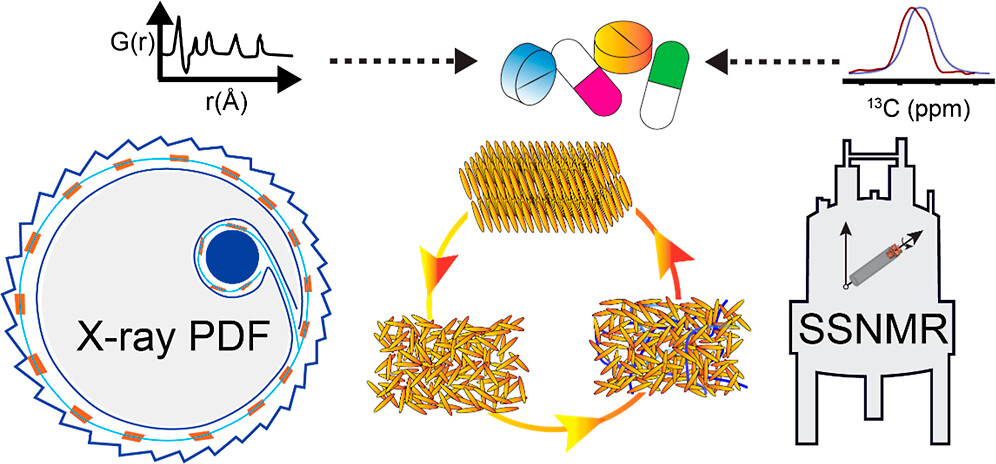

In several recent papers, collaborators from Improved Pharma, Argonne National Laboratory, University of Sao Paulo, Materials Development, Merck, Bristol Myers Squibb, and Purdue University have described analysis of co-processed co-amorphous systems including ketoprofen-polyvinylpyrrolidone (Bhujbal et al., 2021), posaconazole-HPMCAS (Chen et al., 2023), lapatinib-HPMCP (De Araujo et al., 2017), and flubendazole- HPMC (Bezzon et al., 2021). De Araujo, Benmore, and Byrn published a study on the co-amorphous/co-processed lapatinib-HPMCP system. This system contained the cationic lapatinib associated with the anion polymer HPMCP in the amorphous state. The Pair Distribution Function analysis showed that at low drug loading (1:3), domains of the drug were absent, suggesting the formation of a homogeneous solid dispersion with the drug molecules randomly distributed in the polymer. The co-processed/co-amorphous composition with the lack of domains was the most stable composition towards crystallization. Later, DeArujo, Benmore, Byrn, and other collaborators showed similar behavior for flubendazole-HPMCP and HPMCAS polymer co-amorphous/co-processed systems. For the HPMCP and HPMCAS systems, there was lower ordering (reduced domains) in the PDF patterns and greater stability than in the more ordered flubendazole-HPMC system.

In several recent papers, collaborators from Improved Pharma, Argonne National Laboratory, University of Sao Paulo, Materials Development, Merck, Bristol Myers Squibb, and Purdue University have described analysis of co-processed co-amorphous systems including ketoprofen-polyvinylpyrrolidone (Bhujbal et al., 2021), posaconazole-HPMCAS (Chen et al., 2023), lapatinib-HPMCP (De Araujo et al., 2017), and flubendazole- HPMC (Bezzon et al., 2021). De Araujo, Benmore, and Byrn published a study on the co-amorphous/co-processed lapatinib-HPMCP system. This system contained the cationic lapatinib associated with the anion polymer HPMCP in the amorphous state. The Pair Distribution Function analysis showed that at low drug loading (1:3), domains of the drug were absent, suggesting the formation of a homogeneous solid dispersion with the drug molecules randomly distributed in the polymer. The co-processed/co-amorphous composition with the lack of domains was the most stable composition towards crystallization. Later, DeArujo, Benmore, Byrn, and other collaborators showed similar behavior for flubendazole-HPMCP and HPMCAS polymer co-amorphous/co-processed systems. For the HPMCP and HPMCAS systems, there was lower ordering (reduced domains) in the PDF patterns and greater stability than in the more ordered flubendazole-HPMC system.

In another study, a collaboration of Merck scientists and Purdue/Improved Pharma scientists used a combination of PDF and SSNMR to investigate posaconazole amorphous systems.(Chen et al., 2023) Both PDF and SSNMR showed short-range F-C distances. These studies showed the power of utilizing both PDF and SSNMR for analysis of amorphous systems including co-processed systems.

In a very recent publication, Wilke and Weber collaborated with the Improved Pharma/Purdue team to analyze the structures of the ketoprofen-PVP system prepared by five different amorphization techniques: melt quenching, rotary evaporation with vacuum drying, spray drying, and acoustic levitation (Wilke et al., 2024). The PDF analysis showed that the method of amorphization did not greatly influence the structure. This result is consistent with a collaborative study involving Janssen, Panalytical, Argonne, and ImprovedPharma-Purdue scientists.(de Armas et al.) In this case, PDF also showed that co-processed/co-amorphous drug substances prepared by different spray drying processes had similar structures.

Conventional X-ray diffraction has, of course, also been used to analyze co-processed materials. D’Angelo and coworkers used DSC and hot-stage microscopy to screen for co-amorphous/co-processed systems. They ground the drug and an additive into a fine power and utilized DSC or microscopy to determine if an amorphous system was formed.(D’Angelo et al., 2017) In a related study, Kasten and coworkers described a milling-based screen for co-amorphous or co-processed systems.(Kasten et al., 2016) They took six model drugs and milled them with 20 amino acids at 1, 5, 15, 30, and 60 minutes. X-ray powder diffraction was used for analysis. Their studies showed that 15 minutes of grinding was enough to select the best co-process formers. They also found that non-polar amino acids were a good first choice for screening. They showed that tryptophan was able to form co-processed amorphous systems for all four of the model drugs – carbamazepine, simvastatin, furosemide, and indomethacin. Other amino acids did not form co-processed systems.

Erdemir and collaborators published an important paper describing Raman mapping analysis of co-processed metformin HCl and HPMC. Raman mapping was used to determine the co-processed agglomerate composition.(Erdemir et al., 2018) They collected Raman spectra of metformin HCl, HPMC, and the co-processed material using 5-micron spatial resolution. The Raman mapping showed intimate mixing of the metformin HCl and HPMC in the co-processed material but not in the physical mixtures.

IR was used to analyze co-milled products of ibuprofen. Co-milling ibuprofen with seven different excipients was studied for their ability to enhance solubility and flow.(Hussain et al., 2018) Solubility was increased by a factor of 8-10 for soluplus. The method was described as simple, efficient, and economical. IR spectra suggested a change in hydrogen bonding during the co-milling with soluplus.

In an interesting co-processing paper published in 2012, Brettmann, Myerson, and Trout described the application of Solid State NMR to the analysis of a coprocessed three component mixture of aliskiren, indomethacin, and PVP by electrospinning.(Brettmann et al., 2012) They showed that the mixtures prepared by electrospinning were not phase separated, whereas the systems prepared by hot melting methods showed phase separation.

Co-processed materials with reduced melting points have been reported in several instances. Marsec, Li, and Taylor found that miscible systems showed melting point depressions, whereas immiscible systems showed little or no depressions.(Marsac et al., 2009) Screening for melting point reduction provides a powerful strategy to screen for co-processed material with significant interactions and potential improvements of properties. DSC or hot-stage microscopy can be conveniently used to screen for melting point reductions. The application of microscopy to the screening of co-processed material has a substantial advantage because it can work with small amounts of material.

In conclusion, several powerful analytical methods are available for the analysis of co-processed compositions. These methods can differentiate between intimate mixing and physical mixtures, providing a new method for direct characterization. Improved Pharma is well-versed in the utilization of these methods and can assist with the characterization of unique co-processed compositions. Improved Pharma can also utilize these methods in a co-processing screen to find the optimal method to accelerate development.

Bezzon, V. D., Ferreira, F. F., Smith, P., Benmore, C. J., Byrn, S. R., & de Araujo, G. L. (2021). Amorphous dispersions of flubendazole in hydroxypropyl methylcellulose: Formulation stability assisted by pair distribution function analysis. International Journal of Pharmaceutics, 600, 120500.

Brettmann, B., Bell, E., Myerson, A., & Trout, B. (2012). Solid-state NMR characterization of high-loading solid solutions of API and excipients formed by electrospinning. Journal of Pharmaceutical Sciences, 101(4), 1538-1545.

Bhujbal, S. V., Mitra, B., Jian, U., Gon, Y., Agrawal, A., Karki, S., Taylor L. Sl, Kumar, S., Zhour, Q. (2021). Pharmaceutical amorphous solid dispersion: A review of manufacturing strategies. Acta Pharmaceutica Sinica B, 11(8), 2502-2536.

Chen, Z., Nie, H., Benmore, C. J., Smith, P. A., Du, Y., Byrn, S., Templeton, A. C., & Su, Y. (2023). Probing Molecular Packing of Amorphous Pharmaceutical Solids Using X-ray Atomic Pair Distribution Function and Solid-State NMR. Molecular Pharmaceutics, 20(11), 5763-5777.

D’Angelo, A., Edgar, B., & Antonijevic, M. D. (2017). Utilisation of thermal methods for the screening of three component co-amorphous systems. British Journal of Pharmacy, 2(2).

De Araujo, G. L., Benmore, C. J., & Byrn, S. R. (2017). Local structure of ion pair interaction in lapatinib amorphous dispersions characterized by synchrotron X-ray diffraction and pair distribution function analysis. Scientific reports, 7(1), 46367.

de Armas, H. N., Brewster, M., Beckers, D., Gateshki, M., Benmore, C., Van Gelder, J., & Byrn, S. Stability and Comparability of an Amorphous Drug Prepared by Different Spray Drying Processes: Atomic Pair-Wise Distribution Functions (PDF) Using Conventional X-ray Diffraction versus High Energy Synchrotron Radiation.

Erdemir, D., Rosenbaum, T., Chang, S.-Y., Wong, B., Kientzler, D., Wang, S., Desai, D., & Kiang, S. (2018). Novel co-processing methodology to enable direct compression of a poorly compressible, highly water-soluble active pharmaceutical ingredient for controlled release. Organic Process Research & Development, 22(10), 1383-1392.

Hussain, A., Smith, G., Khan, K. A., Bukhari, N. I., Pedge, N. I., & Ermolina, I. (2018). Solubility and dissolution rate enhancement of ibuprofen by co-milling with polymeric excipients. European Journal of Pharmaceutical Sciences, 123, 395-403.

Kasten, G., Grohganz, H., Rades, T., & Löbmann, K. (2016). Development of a screening method for co-amorphous formulations of drugs and amino acids. European Journal of Pharmaceutical Sciences, 95, 28-35.

Marsac, P. J., Li, T., & Taylor, L. S. (2009). Estimation of drug–polymer miscibility and solubility in amorphous solid dispersions using experimentally determined interaction parameters. Pharmaceutical research, 26, 139-151.

Wilke, S. K,. Benmore, C. J., Menron, V., Smith, D., Byrn, S. R., & Weber, R. (2024). Molecular structure of ketoprofen-polyvinylpyrrolidone solid dispersions prepared by different amorphization methods. RSC Pharmaceutics, 1, 121-131.