Co-processed pharmaceutical solids are of considerable interest because of the improvements co-processing can make in a number of solid state properties and pharmaceutical processes. Our first blog on this topic provided a general introduction to co-processed pharmaceutical solids. Examples of crystallization methods with a second component, spherical crystallization, HME prepared solids, and co-processing with an antioxidant were presented. This blog continues the discussion with additional examples, including those involving amorphous materials.

Co-processed pharmaceutical solids are of considerable interest because of the improvements co-processing can make in a number of solid state properties and pharmaceutical processes. Our first blog on this topic provided a general introduction to co-processed pharmaceutical solids. Examples of crystallization methods with a second component, spherical crystallization, HME prepared solids, and co-processing with an antioxidant were presented. This blog continues the discussion with additional examples, including those involving amorphous materials.

Thermal methods of screening for co-processed material with desired properties is of significant interest. D’Angelo and co-workers used DSC and hot-stage microscopy to screen for co-amorphous/co-processed systems. They ground the drug and a co-processor into a fine powder and utilized DSC or microscopy to determine if an amorphous system was formed (D’Angelo et al., 2017). Marsec, Li, and Taylor found that miscible systems showed melting point depressions, whereas immiscible systems showed little or no depressions (Marsac et al., 2009). Screening for melting point reduction provides a powerful strategy to screen for co-processed material with significant interactions and potential improvements of properties. DSC or hot-stage microscopy can be conveniently used to screen for melting point reductions. A new approach, DSC hot-stage microscopy, is ideal if sample size is extremely limited. The application of microscopy to screening of co-processed material has a substantial advantage because it can work with small amounts of material.

In a related study, Kasten and co-workers described a milling-based screen for co-amorphous or co-processed systems (Kasten et al., 2016). They took six model drugs and milled them with 20 amino acids at 1, 5, 15, 30, and 60 minutes. X-ray powder diffraction was used for analysis. Their studies showed that 15 minutes of grinding was enough to select the best co-process formers. They also found that non-polar amino acids were a good first choice for screening. They showed that tryptophan was able to form co-processed amorphous systems for four of the model drugs – carbamazepine, simvastatin, furosemide, and indomethacin. Other amino acids did not form co-processed systems. Co-milling ibuprofen with seven different excipients was studied for their ability to enhance solubility and flow (Hussain et al., 2018). Solubility was increased by a factor of 8-10 for Soluplus®. The method was described as simple, efficient, and economical. IR spectra suggested a change in hydrogen bonding during the co-milling with Soluplus®.

Shah and co-workers utilized solvent-controlled co-precipitation to prepare Zelboraf from the classical “brick dust” drug vemurafenib (Shah et al., 2013). In this process, vemurafenib and HPMCAS were dissolved in DMA, and this solution was introduced into 0.01N HCl. The precipitate was washed and dried to produce a co-amorphous dispersion. Later, Shah and co-workers described a screen based on this process (Hu et al., 2013). This screen utilizes 96 well plates and includes dissolving the drug in DMA, adding it to aqueous solutions filtration, washing, drying, and characterization. They reported this screen could be done on 10 mg of material.

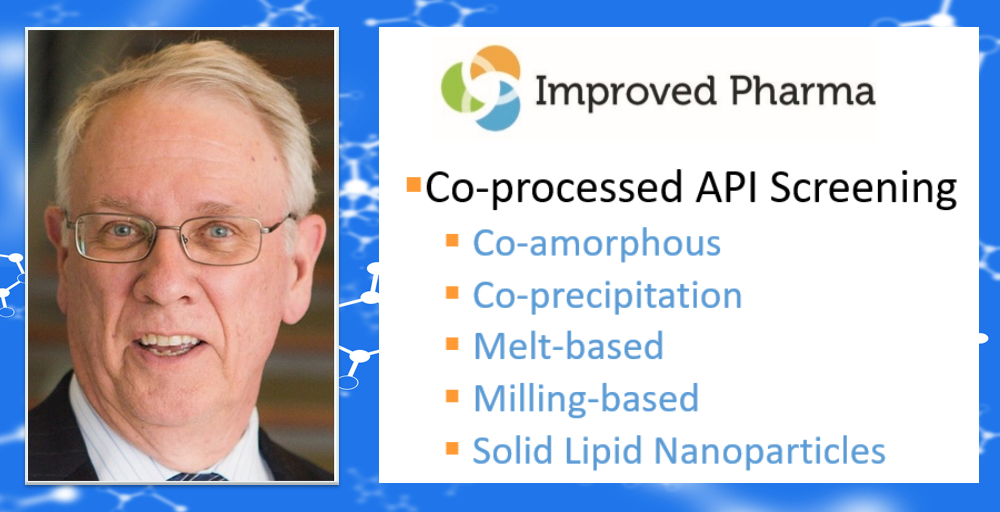

Co-processed drug and polymer systems offer the possibility of improving the solubility and properties of compounds that are difficult to develop. Improved Pharma has described numerous studies on amorphous forms and strategies for analyzing amorphous materials. SSCI, Inc. introduced an amorphous screen in the 1990s and Improved Pharma also offers this type of screen. A typical screen involves co-processing the API with polymeric additives, excipients, and in some cases, a third component like a surfactant or special solvent like cremophor. Processing involves dissolution in a solvent and evaporation with or without high vacuum, milling the components, or melt-cooling the components if they are heat stable. The formation of amorphous material is typically confirmed by X-ray powder diffraction, but the process can be performed in well plates and analyzed microscopically to conserve materials. Clearly, such a study can require a very large number of experiments. These numbers are typically reduced using a consideration of the API and its properties. Once prepared, the stability of the dispersion is examined using stress conditions.

If a lead co-processed composition is discovered by screening, the next step is to scale up. Normally, scale-up is done in increments of 10x with continued analysis of the co-processed product, including stability to ensure the viability of the composition. Compositions failing to show good stability or other desirable properties are rejected. In some cases, it may be necessary to repeat the screen, focusing on solving the problems observed during the scale-up.

In conclusion, screening for co-processed material typically involves a subset of the above studies and those discussed in the first blog. The screens should be tailored to the properties of the API, the eventual desired dosage form, and the desired approach to scale up. The overall goal is to reduce the time to IND by merging drug substance and drug product studies into one co-processing step.

D’Angelo, A., Edgar, B., & Antonijevic, M. D. (2017). Utilisation of thermal methods for the screening of three component co-amorphous systems. British Journal of Pharmacy, 2(2), S23-25.

Hu, Q., Choi, D. S., Chokshi, H., Shah, N., & Sandhu, H. (2013). Highly efficient miniaturized co-precipitation screening (MiCoS) for amorphous solid dispersion formulation development. International Journal of Pharmaceutics, 450(1-2), 53-62.

Hussain, A., Smith, G., Khan, K. A., Bukhari, N. I., Pedge, N. I., & Ermolina, I. (2018). Solubility and dissolution rate enhancement of ibuprofen by co-milling with polymeric excipients. European Journal of Pharmaceutical Sciences, 123, 395-403.

Kasten, G., Grohganz, H., Rades, T., & Löbmann, K. (2016). Development of a screening method for co-amorphous formulations of drugs and amino acids. European Journal of Pharmaceutical Sciences, 95, 28-35.

Marsac, P. J., Li, T., & Taylor, L. S. (2009). Estimation of drug–polymer miscibility and solubility in amorphous solid dispersions using experimentally determined interaction parameters. Pharmaceutical research, 26, 139-151.

Narala, S., Nyavanandi, D., Srinivasan, P., Mandati, P., Bandari, S., & Repka, M. A. (2021). Pharmaceutical Co-crystals, Salts, and Co-amorphous Systems: A novel opportunity of hot-melt extrusion. Journal of drug delivery science and technology, 61, 102209.

Shah, N., Iyer, R. M., Mair, H.-J., Choi, D., Tian, H., Diodone, R., Fahnrich, K., Pabst-Ravot, A., Tang, K., & Scheubel, E. (2013). Improved human bioavailability of vemurafenib, a practically insoluble drug, using an amorphous polymer-stabilized solid dispersion prepared by a solvent-controlled co-precipitation process. Journal of Pharmaceutical Sciences, 102(3), 967-981.