Scanning electron microscopy (SEM) is a technique used for the observation and characterization of heterogeneous inorganic and organic materials on a micrometer (mm) to nanometer (nm) scale. In the SEM analysis of a sample, the area to be imaged is irradiated with a finely focused electron beam. The interaction of the electron beam with the sample produces a variety of signals such as secondary electrons, backscattered electrons, characteristic X-rays, Auger electrons, and ultraviolet, visible and infrared photons of various energies. The signals of primary interest for the SEM analysis are the secondary and backscattered electrons. The three-dimensional appearance of the image is due primarily to the large depth of field of the scanning electron microscope as well as the shadow relief effect of the secondary electrons, and the contrast from the backscattered electrons. A scanning electron microscope is one of the most versatile instruments available for examination and analysis in the biological, geological, chemical, and pharmaceutical sciences to visualize samples. The information gained from these analyses includes surface topography, morphology, composition, surface structure and features, among other properties.

Variable Pressure/Environmental Scanning Electron Microscopy (VP/ESEM) refers to an instrumental technique that can image a sample in a gas maintained at a pressure in the specimen chamber of between approximately 10 to 2,700 Pa (0.1 to 20 Torr). VP-ESEMs are usually designed to operate optimally in the electron beam energy range 10-30 keV rather than at the lower energy of 1-5 keV of a conventional high-vacuum SEM. Cooling a specimen to approximately 0 °C before evacuating the VPSEM sample chamber may slow the kinetics of the liquid-gas transformation enough to observe and image a wet specimen before it is significantly altered by drying. Some viscous, ionic liquids exhibit pressure-temperature relations that permit equilibrium with the gas phase under the pressure-temperature conditions achievable in a VPSEM.

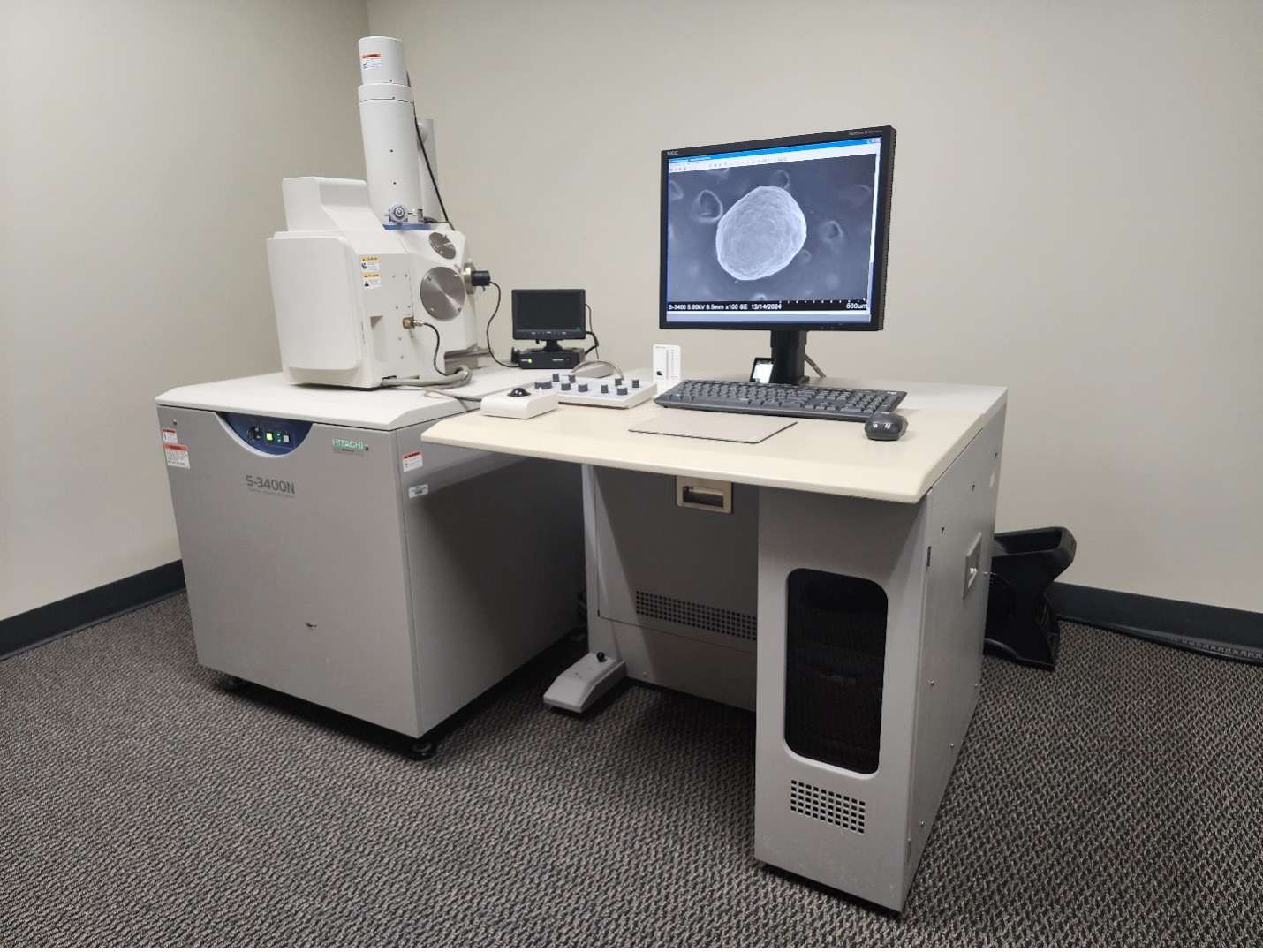

The Improved Pharma & Chemical Microscopy SEM Laboratory houses an Hitachi S3400N Type II variable pressure scanning electron microscope equipped with ultra large specimen chamber, which accommodates 300 mm diameter specimens up to 60 mm in height, low vacuum range 6-270 Pa, 5-axis motorized computer eucentric stage (100 mm x 50 mm), 360° rotating stage with 20°-90° tilt, 130 mm observable area, tungsten filament electron source, Everhart-Thornley secondary electron (SE) detector, 5 segment solid-state backscattered electron (BSE) detector with Topo, Compo and 3D Mode, environmental secondary electron (ESE) detector, chamber scope, and Deben Coolstage. The variable pressure SEM can operate with an accelerating voltage 0.3 – 30 kV to obtain a 5x to 300,000x magnification with approximately 3 nanometer spatial resolution using SE at 30 kV and approximately 4 nanometer spatial resolution using BSE at 30 kV.

Our laboratory is equipped with an assortment of sample preparation tools and equipment to facilitate specimen preparation of small samples, which includes forceps, probes, needles, razor blades and scalpels, brushes, pipettes, scissors, saws, grinders, a mini vice, and a variety of different size and shape microsurgical tools. Carbon and aluminum sample support stubs in various sizes, double-sided adhesive carbon tabs, conductive tape, conductive paint, copper or aluminum conductive tape. We use gold, platinum, gold/palladium, silver, and carbon sample coatings, which are some of the most common conductive surface coatings. The very thin layer (1-2 nanometer) of film deposited on the sample provides a ground plane rather than rendering the surface conductive. The function of the thin layer(s) of conductive material is to increase the surface electrical conductivity of the sample, to increase the surface thermal conductivity, and potentially increase the secondary electron and backscattered electron signal from the sample.

In the research and development of a pharmaceutical drug substance, the primary objective of SEM analysis is to acquire photomicrographs of representative crystals for evaluation of size range, morphology, agglomeration, and comparative analysis of batch-to-batch consistency or sameness. Samples that are milled and micronized typically form agglomerates. These agglomerates can be classified as weak or strong, which refers to their tendency to resist dispersion and separation. In most cases, the analysis consists of the number and primary particle size and shape.

Microtomy (microtome) is the technique of cutting sections suitable for examination by transmission or reflection microscopy. A microtome is made up of a specimen holder, a feeding mechanism designed to control the thickness of the section, and a knife support and guide. Microtomes range in size from a small, hand-held Hardy-type, a small table top Schwarz Fiber Microtome, to a large bench top models used for three dimensional specimens. These techniques can accommodate samples that are generally prepared by impregnating, polymerizing, or fixing to a support prior to analysis. Our SEM sample preparation lab has a variety hand-held, rotary, and sliding (sledge) microtomes.