Improved Pharma has extensive experience with solving problems in operations and quality, especially related to production systems. This experience is based on many years of consulting for the pharmaceutical industry. Even as early as 1980, Improved Pharma scientists solved problems related to stability failures and OOS results. Improved Pharma also provides solutions to formulation failures and suggests reformulation strategies. Improved Pharma, because of its extensive expertise in solid state chemistry, is skilled at addressing polymorph failures and batch manufacturing problems. Improved Pharma’s link to Chemical Microscopy LLC provides advanced microscopic methods to address contamination issues. In summary, Improved Pharma provides input into a range of critical regulatory documents, including the selection of Critical Process Parameters (CPPs) and Critical Material Attributes (CMAs), and ways to address FDA and internal audit observations.

Improved Pharma offers a full suite of troubleshooting services and is working on problems such as

- Appearance of a new form

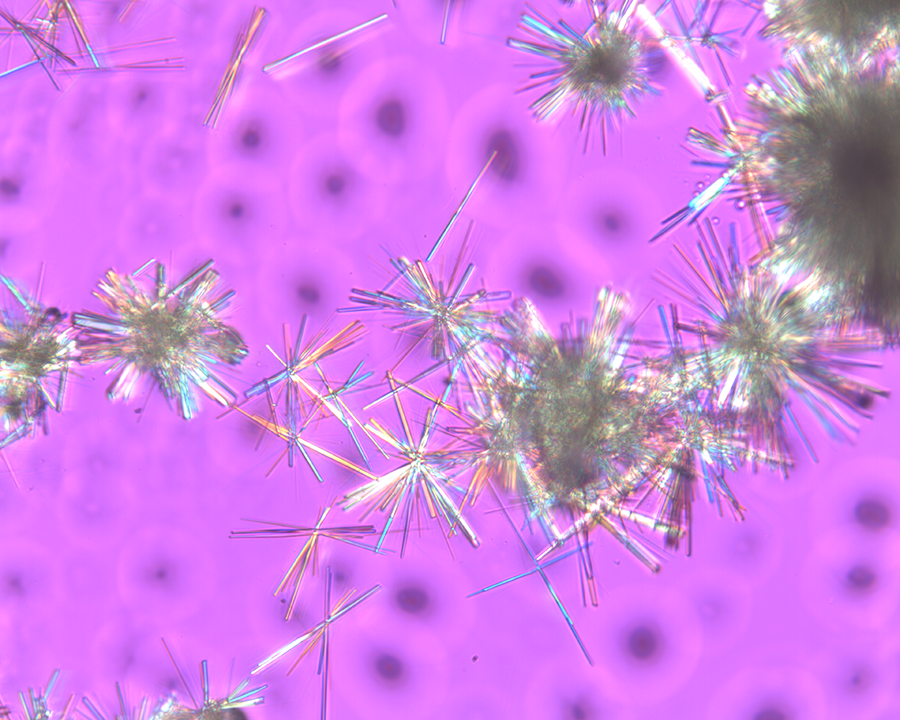

- Methods development to detect forms including Synchrotron-based methods

- Salt discovery and analysis including Raman and Infrared microspectroscopy and single-crystal methods

- Intellectual property issues

- Fast to IND services (fIND)

- Stability studies

- Detection of domains in amorphous and microsphere formulations related to stability failures

- Regulatory issues related to solid forms

Improved Pharma typically diagnoses the problem using the client’s data supplemented with analysis by Synchrotron X-ray diffraction and/or the latest microspectroscopy methods. Improved Pharma is also skilled at using standard methods like DSC, HPLC, microscopy, or dissolution in unique ways to provide rapid diagnosis. Also, if required, these methods are included in development reports to address regulatory issues. Contact Improved Pharma to apply a wide range of modern methods to solve operations, quality, and regulatory problems.