Solving Pharmaceutical Problems

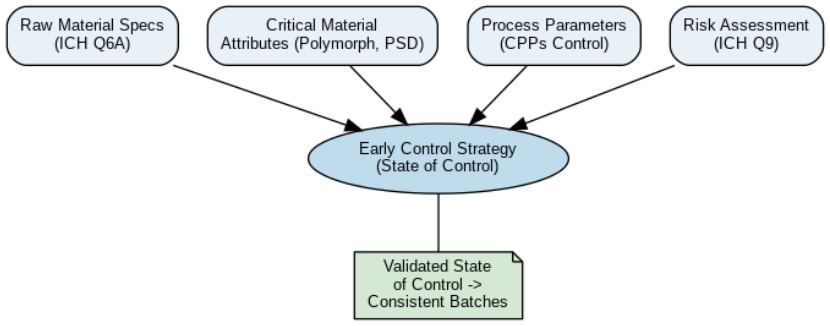

Improved Pharma is a research and information company dedicated to improving pharmaceutical methods, formulations, and processes. Services include solid-state form studies, formulation design, synchrotron techniques, analytical testing, and expert consulting for the development and defense of intellectual property matters. The company was founded in 2006 by Stephen and Sarah Byrn, who also founded SSCI.

Analytical Testing Services

“Testing, understanding, monitoring, and controlling drug development”

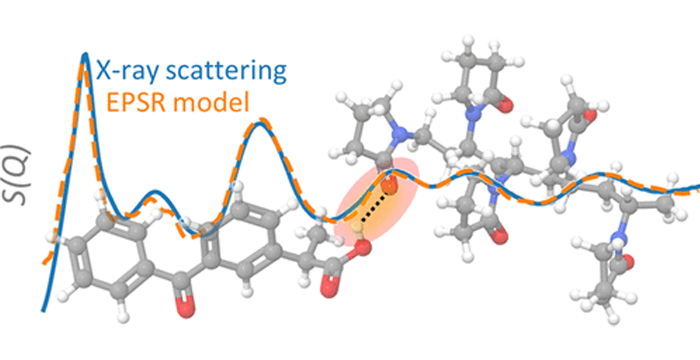

Solid-State Form Studies

“Strategies for understanding the solid-state landscape of a drug”

Microscopy

“Combining microscopy and analytical instrumentation to probe drug substances and products on a micron level”

Presentations and Publications

Combined years of experience in the field

Percent passion for what we do